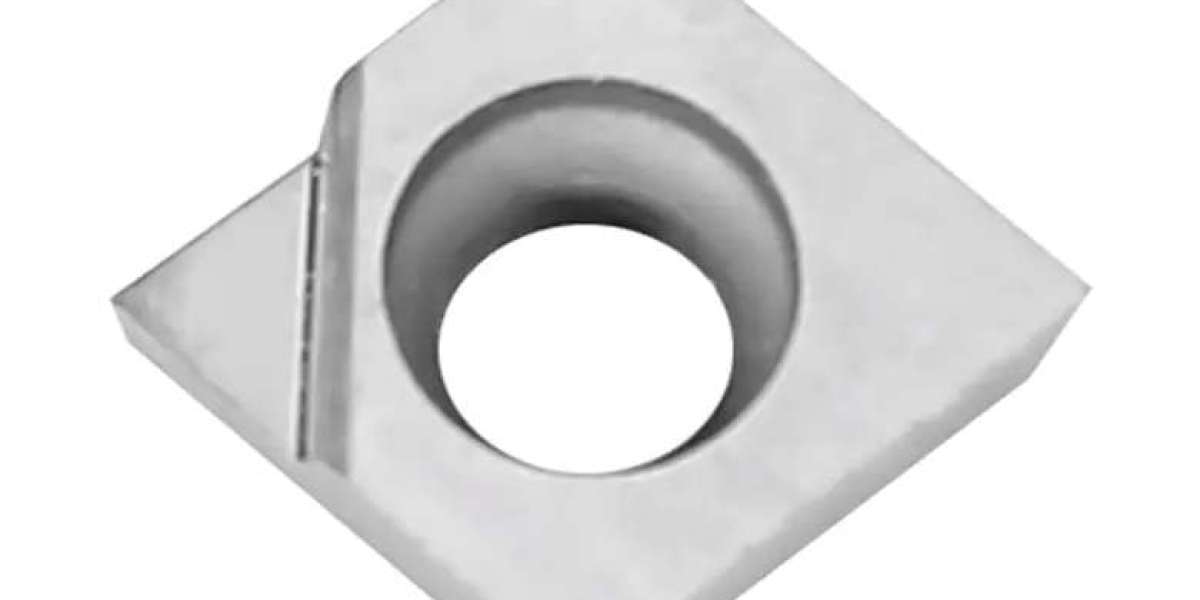

A well-designed Indexable Insert ensures reliable cutting performance and consistent quality in metalworking operations. The insert’s structure, material, and coating must work together to deliver stability during various cutting conditions. Our company produces inserts made from premium tungsten carbide powders, sintered under high temperature and pressure to achieve uniform density and toughness.

Edge geometry is one of the most critical elements in insert design. Properly prepared cutting edges control chip direction, reduce tool wear, and enhance surface finish. Depending on the machining type—finishing, semi-finishing, or roughing—the insert shape and corner radius are adjusted accordingly. This precision allows operators to achieve optimal results in both high-speed and interrupted cuts.

To ensure consistency, we utilize advanced CNC grinding machines for edge processing. Each insert is inspected for tolerance accuracy before coating. Surface coatings are carefully selected according to customer requirements—TiN, TiAlN, or Al₂O₃ layers improve oxidation resistance and minimize friction.

Customization is another key strength. We accept technical drawings or samples to produce non-standard inserts suited for specific cutting tools. Whether used in steel machining, woodcutting, or composite processing, each product reflects our focus on durability and efficiency.

Through years of practical experience, we have developed a comprehensive understanding of how insert materials behave under different forces. By optimizing microstructure and edge design, our inserts achieve a balanced combination of hardness, wear resistance, and toughness. This balance is what makes them reliable across diverse machining environments, helping manufacturers maintain stable quality and operational efficiency.