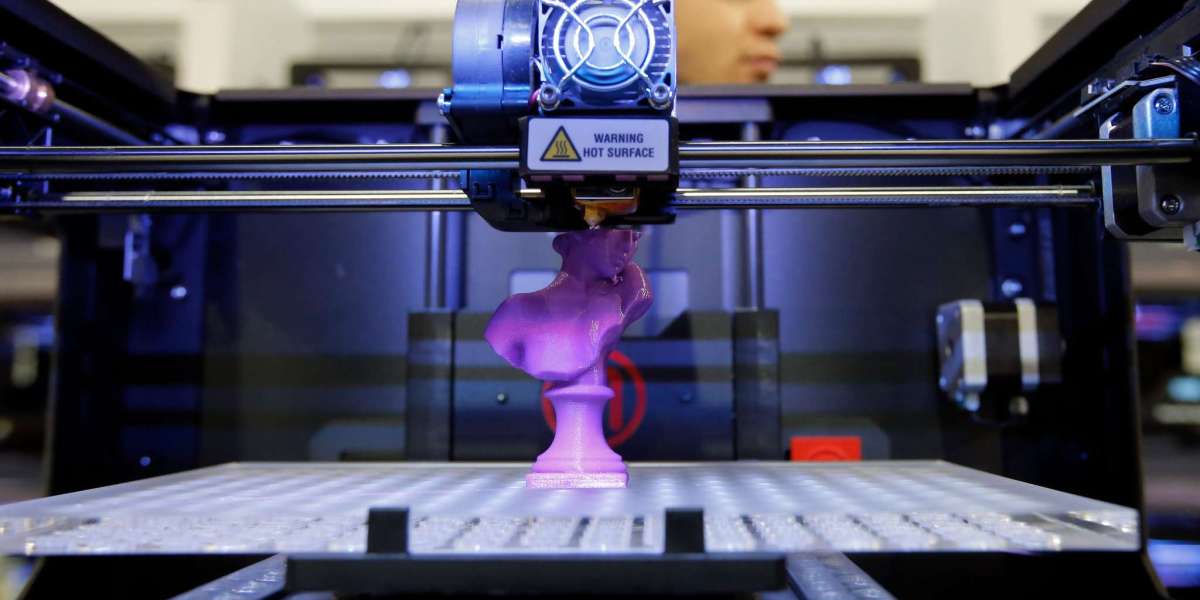

The global 3D printing market has evolved from a niche prototyping tool into a transformative manufacturing technology reshaping multiple industries. Once limited to design and model development, additive manufacturing is now used for end-use parts, customized products, and rapid production. In 2024, the global 3D printing market size was valued at approximately USD 13.20 billion and is projected to reach USD 34.60 billion by 2032, growing at a compound annual growth rate (CAGR) of around 14.80% during the forecast period.

This impressive growth is fueled by increasing adoption across sectors such as aerospace, automotive, healthcare, defense, construction, and consumer goods. The technology’s ability to reduce waste, improve production flexibility, and create complex geometries that traditional manufacturing cannot achieve makes it one of the most disruptive innovations of the modern era.

Competitive Landscape

The 3D printing market is highly competitive and fragmented, featuring a mix of global industry leaders, regional specialists, and emerging startups. Companies compete on technology innovation, speed, precision, material range, and software integration.

Prominent players include Bright Laser (China), Xometry (U.S.), Farsoon (China), Protolabs (U.S.), Stratasys (U.S./Israel), Nano Dimension (Israel), 3D Systems (U.S.), Materialise (Belgium), Desktop Metal (U.S.), Titomic (Australia), BigRep (Germany), Markforged (U.S.), AML3D (Australia), Aurora Labs (Australia), Massivit (Israel), Velo3D (U.S.), Freemelt (Sweden), Steakholder Foods (Israel), Sygnis (Germany), FATHOM (U.S.). These companies have extensive product portfolios spanning polymer, resin, and metal 3D printers, as well as advanced software and cloud-based printing services.

Request Sample For 3D Printing Market @ https://www.databridgemarketresearch.com/request-a-sample?dbmr=global-3d-printing-market

Key Market Drivers

Rising Adoption in Manufacturing and Prototyping

One of the primary drivers of the 3D printing market is the growing adoption in industrial production. Manufacturers use 3D printing to create prototypes, tooling, molds, and final-use components faster and at lower cost. It enables product designers to iterate rapidly and reduces time-to-market, helping companies maintain a competitive edge.

In the automotive and aerospace industries, 3D printing helps produce lightweight and complex parts that improve fuel efficiency and performance. Healthcare providers are leveraging 3D printing for customized implants, prosthetics, and surgical models, enhancing patient outcomes and precision in treatment.

Technological Advancements

Advancements in materials, hardware, and software are expanding the capabilities of 3D printing. New materials such as high-strength polymers, composites, ceramics, and metals now allow production of durable and functional components. Printers are becoming faster, more accurate, and capable of handling larger-scale projects.

At the same time, AI and automation are being integrated into 3D printing workflows to optimize print parameters, reduce waste, and predict quality outcomes. Cloud-based software platforms also enable remote collaboration, fleet management, and real-time monitoring of additive manufacturing processes.

Market Segmentation Insights

By Component

The 3D printing market is segmented into hardware, software, and services. Hardware—comprising 3D printers and materials—remains the dominant segment, accounting for the majority of market revenue. However, software and services are growing rapidly as companies increasingly rely on cloud-based design platforms and on-demand printing services for scalability and cost-efficiency.

By Technology

Key 3D printing technologies include Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), Direct Metal Laser Sintering (DMLS), and Binder Jetting. Among these, FDM is the most widely used due to its affordability and versatility, while metal 3D printing technologies are gaining traction for industrial and aerospace applications.

By Material

The market uses a diverse range of materials such as polymers, resins, metals, ceramics, and composites. Metal-based 3D printing is expanding rapidly due to demand from aerospace, defense, and energy sectors, which require high-strength and heat-resistant parts.

By End User

Major end users include automotive, aerospace, healthcare, defense, consumer electronics, construction, and education. Healthcare is expected to witness the fastest growth due to increasing use of bioprinting and patient-specific solutions.

Regional Analysis

North America dominates the global 3D printing technology due to strong industrial adoption, technological leadership, and a robust ecosystem of manufacturers and research institutions. The region is home to several major 3D printing companies and enjoys high R&D spending across automotive, defense, and healthcare sectors.

Europe follows closely, supported by significant government initiatives promoting Industry 4.0 and additive manufacturing. Countries such as Germany, the UK, and France are major hubs for innovation, particularly in aerospace and automotive production.

The Asia-Pacific region is expected to record the fastest growth rate during the forecast period. Rapid industrialization, government investment in digital manufacturing, and the growing electronics and automotive industries in China, Japan, South Korea, and India are fueling demand for 3D printing technologies.

Regions such as Latin America, the Middle East, and Africa are witnessing steady growth as manufacturers explore 3D printing for low-volume production, spare parts manufacturing, and architectural design.

Strategic Initiatives

To strengthen market presence, key players are engaging in strategic mergers, acquisitions, and partnerships. These collaborations help expand their technology capabilities, global footprint, and customer base. Many vendors are also investing in R&D to develop next-generation printers with faster print speeds, multi-material compatibility, and AI-enabled quality control.

For More Reports:

About Us:

Data Bridge is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact:

Data Bridge Market Research Private Ltd .

3665 Kingsway — Suite 300 Vancouver BC V5R 5W2 Canada

+1 614 591 3140 (US)

+44 845 154 9652 (UK)