When a Manitowoc crane stops working, the cost of downtime can add up fast. If the hydraulic pump is the problem, ordering the right replacement is essential to getting the crane back online. As one of the most critical Manitowoc crane parts, the hydraulic pump drives essential functions like boom movement, winch operation, and outrigger stabilization. A mistake in ordering can lead to prolonged delays, system damage, or significant expenses.

This guide provides a step-by-step process for sourcing the correct hydraulic pump and highlights why partnering with a dependable crane parts supplier can prevent costly errors.

Why Precision Matters

The hydraulic pump is the heart of a Manitowoc crane’s hydraulic system, delivering the fluid pressure needed for powerful and precise operation. A pump that doesn’t match the crane’s specifications—whether in flow rate, pressure, or physical design—can cause serious issues.

For example, a pump with too high a flow rate can overpressurize the system, leading to overheating or component failure. A pump with insufficient flow may result in sluggish movements or inability to lift loads. Even a minor mismatch, like an incompatible drive shaft or mounting flange, can prevent installation. When dealing with Manitowoc crane parts, accuracy is non-negotiable.

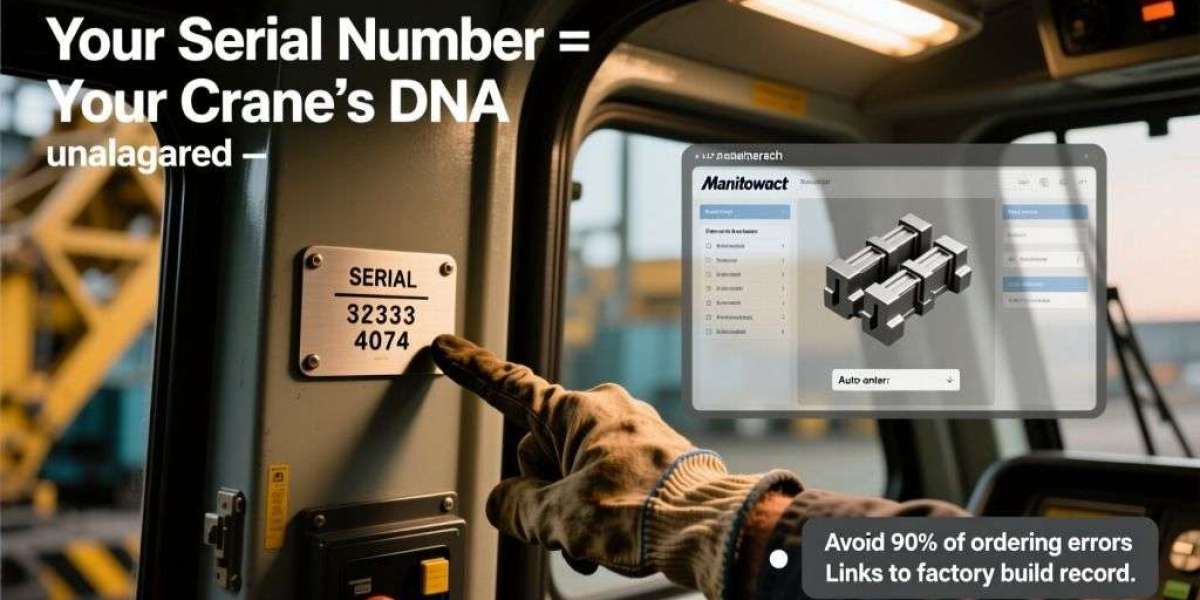

Step 1: Locate the Serial Number

The crane’s serial number is your starting point for identifying the correct hydraulic pump. This unique identifier, typically found on a plate on the crane’s frame or in the operator’s cab, links directly to the crane’s original manufacturing records. These records list all factory-installed components, including the hydraulic pump, engine, and gearbox.

By providing the serial number to a crane parts supplier, you enable them to access Manitowoc’s parts catalog and pinpoint the exact pump model for your crane. This step eliminates guesswork and prevents most ordering mistakes.

Step 2: Verify the Part Number

Each hydraulic pump has a unique part number, usually stamped on a metal tag or engraved on the pump’s body. This number specifies the pump’s displacement, shaft type, and mounting configuration. If the tag is illegible or missing, a crane parts supplier can use the crane’s serial number to retrieve the correct part number.

Precision is critical. A single character difference in the part number could indicate a pump with a different flow rate or mounting pattern, even if it looks similar externally. For older Manitowoc cranes, part numbers may have been updated due to design improvements, and a supplier can confirm if a newer part has superseded the original.

Step 3: Understand the Pump’s Function

Manitowoc cranes often use multiple hydraulic pumps, each tailored to specific tasks like swing, boom hoist, or auxiliary systems. These pumps may vary in design—single, tandem, or multi-section—depending on the crane’s setup. Ordering a pump for the wrong function is a common error that can halt operations.

To avoid this, document the pump’s location and connections before removing it. Clear photos of the pump and its surrounding components can help your crane parts supplier verify the correct Manitowoc crane parts, especially when paired with the serial number.

Step 4: Confirm the Drive Mechanism

Manitowoc cranes use either gear-driven or direct-drive hydraulic pumps, and the drive type affects the pump’s shaft, mounting, and operational speed. Installing a direct-drive pump in place of a gear-driven one (or vice versa) will cause immediate issues due to incompatible mechanics.

Before ordering, note details like the spline count, shaft diameter, and mounting bolt pattern. These specifics ensure the replacement pump integrates seamlessly with your crane’s system. If you’re unsure, consult your supplier for assistance.

Step 5: Check Pressure and Flow Requirements

Each Manitowoc crane model requires a pump with specific pressure and flow ratings to deliver the necessary power and speed. A pump with incorrect ratings can strain the system, damaging components like hoses, valves, or cylinders, and leading to costly repairs.

If the pump’s rating plate is missing, a crane parts supplier can retrieve the correct specifications using the crane’s serial number or technical documentation. Verifying these details upfront prevents system-wide issues.

The Value of a Reliable Crane Parts Supplier

A trusted crane parts supplier does more than fulfill orders—they ensure you get the right Manitowoc crane parts for your specific needs. They’ll verify serial numbers, cross-reference part numbers, and confirm the pump’s compatibility with your crane’s configuration. For older models, they can identify whether a pump is still in production or if a compatible replacement is available.

Suppliers specializing in Manitowoc crane parts have access to detailed manufacturer data and cross-reference tools, which streamline the ordering process and reduce the risk of mistakes. Their expertise saves time and prevents costly errors.

The Risks of a Mismatch

Ordering the wrong hydraulic pump can lead to serious consequences. Beyond the cost of the part itself, a mismatch can contaminate the hydraulic system, damage seals, or cause a complete shutdown. Even brief operation with an incorrect pump can necessitate extensive repairs, prolonging downtime.

Taking the time to confirm details like part numbers and specifications ensures a smooth replacement process and keeps your crane operational.

Rebuild or Buy New?

In some cases, rebuilding a hydraulic pump can be a cost-effective alternative to purchasing a new one. If the pump’s housing, shaft, and internal components are in good condition, a rebuild kit can restore performance at a lower cost. However, severe damage, like a cracked housing or worn gears, may require a full replacement.

A crane parts supplier can evaluate the pump and advise whether rebuilding is viable. They can also provide rebuild kits tailored to your pump’s specific part number.

Conclusion

Sourcing the correct hydraulic pump for a Manitowoc crane requires careful attention to detail. Start with the crane’s serial number, verify the pump’s part number, confirm its function and drive type, and ensure the pressure and flow ratings align. Working with an experienced crane parts supplier simplifies the process and ensures accuracy.

By following these steps, you can avoid costly delays and keep your Manitowoc crane running smoothly. A few minutes spent double-checking details can save hours of downtime, ensuring your crane is back on the job where it belongs.