Learn which key features to look for in a fiber laser cutting machine to ensure maximum effectiveness and performance.

Power and Precision

Power and accuracy are two of the most important factors to take consideration when purchasing a fiber laser cutting machine. You can cut through a variety of materials with different thicknesses according to the system's cutting capabilities, which are determined by the laser's power. You are able to perform more difficult tasks with higher power lasers since they are more versatile and can handle a wider range of thicker materials.

While it affects the accuracy and quality of the cuts, precision is equally important. To ensure consistently clean and accurate cuts, look for a machine with excellent precision. This is particularly crucial for industries like electronics, automotive, and aerospace that need accurate and detailed cutting.

Purchasing a fiber laser cutting machine that is both powerful and accurate will provide you the adaptability and precision you need to satisfy your unique cutting needs.

Cutting Speed and Acceleration

Cutting speed and acceleration are key features to take into account when buying a fiber laser cutting machine. Acceleration is the rate at which the laser may change direction or start and stop, whereas cutting speed is the rate at which the laser may move through the material. The drives' "G" rating affects acceleration as well. For low-powered machines, a 1G acceleration machine is fine; however, if you're looking at 6KW or more, you should think about a design that offers 2G or higher acceleration rates. The faster the machine can cut complicated components, the more efficiently it can use higher wattage power sources.

You may finish tasks faster with a faster cutting speed and acceleration, which can greatly increase production and efficiency. This is particularly useful for industries that need to produce large quantities.

The particular requirements of your company and the kinds of materials you operate with must be taken into account when assessing cutting speed and acceleration. The secret to getting the best results is to find a balance between speed and accuracy.

Ease of Use and Maintenance

When buying a fiber laser cutting machine, ease of use and maintenance are important considerations. Look for a machine with an easy-to-use UI and intuitive controls. This will save downtime and increase production by allowing your operators to get proficient with the machinery fast.

Also, consider the system's maintenance needs. Choose a machine that is simple to maintain, with easily accessible parts and clear maintenance guidelines. To maintain the system's longevity and optimal performance, regular maintenance is necessary.

Buying a fiber laser cutting machine that is simple to operate and maintain will ultimately save you time and money while increasing production and efficiency.

Software and Technology Integration

A fiber laser cutting machine functionality and usability can be significantly impacted by the software and technological integration. Look for a system with advanced software features like nesting optimization and CAD/CAM interoperability.

Importing and using cutting files is made easier by CAD/CAM compatibility, which enables seamless integration with design tools. Software for nesting optimization maximizes material use, minimizes waste, and improves manufacturing efficiency.

Additionally, take into account the machine's compatibility with other technologies and communication possibilities. Streamlining processes and increasing overall efficiency can be achieved through integration with automation systems and industry-specific software.

Purchasing a fiber laser cutting machine with advanced software and technological integration will give you the resources and skills required to maintain your competitiveness in the rapid manufacturing world of today.

Support and Service

It's important to take the manufacturer's support and service into consideration when buying a fiber laser cutting machine. Look for a reputable manufacturer that provides thorough customer care and quick help.

Take into consideration factors like technical support, spare component availability, and warranty coverage. A reliable manufacturer will minimize downtime and guarantee seamless operations by offering quick support in the event of any problems or breakdowns.

To determine the manufacturer's reputation for customer satisfaction and after-sales service, look into customer reviews and feedback. You will feel more at ease and confident about your investment if you choose a reputable manufacturer with first-rate support and service.

You can guarantee an easy purchasing process and long-term satisfaction with your fiber laser cutting machine by giving support and service top priority.

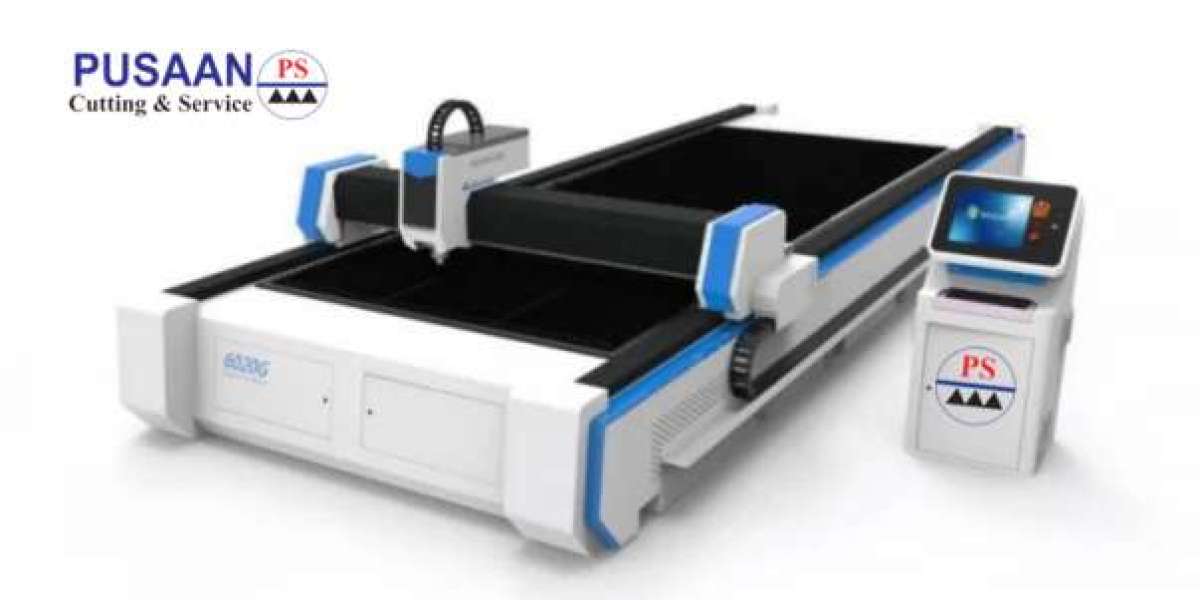

At Pusaan Automation, we are knowledgeable in fiber lasers and can help you in choosing the best machine, new or old, for your needs and budget.