Linear Guide Bearings: Core Characteristics

Linear guide bearings consist of:

A guide (rail) with precision-machined raceways.

A slider (carriage/block) containing rolling elements (balls or rollers) or sliding surfaces (e.g., PTFE).

A mechanism to reduce friction (rolling or optimized sliding).

Key Advantages:

✔ Low friction and smooth motion

✔ Moderate to high load capacity

✔ Cost-effective and versatile

✔ Achievable precision (up to ±0.001 mm in high-end designs)

Comparison with Alternative Systems

1. Linear Guide Bearings vs. Ball Screws

Ball screws convert rotary motion to linear motion using a threaded shaft and nut with recirculating balls.

Factor | Linear Guide Bearings | Ball Screws | Advantage |

|---|---|---|---|

Motion Type | Direct linear motion (slider + guide) | Rotary-to-linear motion (shaft + nut) | Slides for multi-axis flexibility; ball screws for pure thrust. |

Load Capacity | Up to 100,000N (heavy-duty sliders) | Up to 100,000N | Slides handle combined radial/axial loads better. |

Precision | ±0.001 mm (high-end designs) | ±0.0001 mm (exceptional for thrust) | Ball screws for ultra-high precision in thrust applications. |

Speed | Up to 2 m/s (optimized designs) | Up to 1 m/s | Slides faster in dynamic applications. |

Backlash | Minimal (with preloaded sliders) | Minimal (inherent in design) | Comparable, but slides manage side loads more effectively. |

Best For | Multi-axis systems, heavy loads | High-thrust tasks (e.g., presses) | Choose slides for versatility; ball screws for thrust. |

Insight: Ball screws excel at converting rotary motion to linear with extreme precision, making them ideal for tasks like hydraulic presses or screw-driven linear actuators. However, linear guide bearings are more versatile for multi-axis systems and can handle heavier combined loads.

2. Linear Guide Bearings vs. Belt-Driven Systems

Belt drives use a motorized pulley and belt to create linear motion.

Factor | Linear Guide Bearings | Belt-Driven Systems | Advantage |

|---|---|---|---|

Load Capacity | Up to 100,000N (heavy-duty sliders) | Up to 1,000–5,000N (typical for most belts) | Slides for heavy loads; belts for light loads. |

Speed | Up to 2 m/s (optimized sliders) | Up to 10 m/s | Belts for high-speed tasks. |

Precision | ±0.001 mm (high-end sliders) | ±0.01–0.1 mm (limited by belt elasticity) | Slides for accurate positioning. |

Rigidity | High (resists deflection) | Low (belts can stretch or vibrate) | Slides for stable motion. |

Cost | Moderate to High | Low | Belts are budget-friendly for non-critical tasks. |

Best For | Precision, heavy loads | High-speed, light loads (e.g., conveyors) | Choose slides for precision; belts for speed/cost. |

Insight: Belt-driven systems are cost-effective and ideal for high-speed applications (e.g., conveyor belts, pick-and-place machines), but they lack the precision, rigidity, and load capacity of linear guide bearings.

3. Linear Guide Bearings vs. Linear Motors

Linear motors produce direct linear motion without mechanical contact, using electromagnetic force.

Factor | Linear Guide Bearings | Linear Motors | Advantage |

|---|---|---|---|

Motion Type | Mechanical (rolling or sliding) | Electromagnetic (no physical contact) | Motors for speed/no friction; slides for reliability. |

Load Capacity | Up to 100,000N (heavy-duty sliders) | Up to 20,000–50,000N (limited by magnetic force) | Slides for heavier loads. |

Speed | Up to 2 m/s (optimized sliders) | Up to 20 m/s | Linear motors for extreme speed. |

Acceleration | Moderate (depends on drive) | Very High (instant thrust) | Linear motors for rapid starts/stops. |

Complexity | Simple (mechanical components) | Complex (requires power electronics, cooling) | Slides for easier maintenance. |

Best For | Reliable, moderate-speed motion | Ultra-high speed, short-stroke tasks | Choose slides for everyday use; motors for specialized high-speed apps. |

Insight: Linear motors are the fastest linear motion solution (e.g., maglev trains, high-speed sorting systems), but they are more expensive, complex, and have lower load capacity compared to linear guide bearings, which are better suited for general industrial use.

4. Linear Guide Bearings vs. Plain Bearings (Sliding Contact)

Plain bearings rely on direct sliding contact between the slider and guide (e.g., bronze, polymer, or PTFE-coated surfaces).

Factor | Linear Guide Bearings | Plain Bearings | Advantage |

|---|---|---|---|

Friction | Low (rolling or optimized sliding) | High (direct surface contact) | Slides for smoother, more efficient motion. |

Wear and Maintenance | Minimal (rolling elements last longer) | High (wear occurs quickly, requires frequent replacement) | Slides for longer lifespan. |

Precision | ±0.001 mm (high-end sliders) | ±0.1–1 mm (limited by surface roughness) | Slides for accurate positioning. |

Load Capacity | Up to 100,000N (heavy-duty sliders) | Up to 1,000–5,000N (limited by material strength) | Slides for heavier loads. |

Best For | High-precision, high-load applications | Low-cost, low-load tasks (e.g., simple drawer slides) | Choose slides for performance; plain bearings for simplicity. |

Insight: Plain bearings are inexpensive and easy to manufacture, but they suffer from high friction, rapid wear, and limited precision. Linear guide bearings, even basic models, offer superior performance for demanding tasks.

Hybrid Systems: Combining Technologies

Many advanced systems integrate linear guide bearings with other components to leverage their strengths:

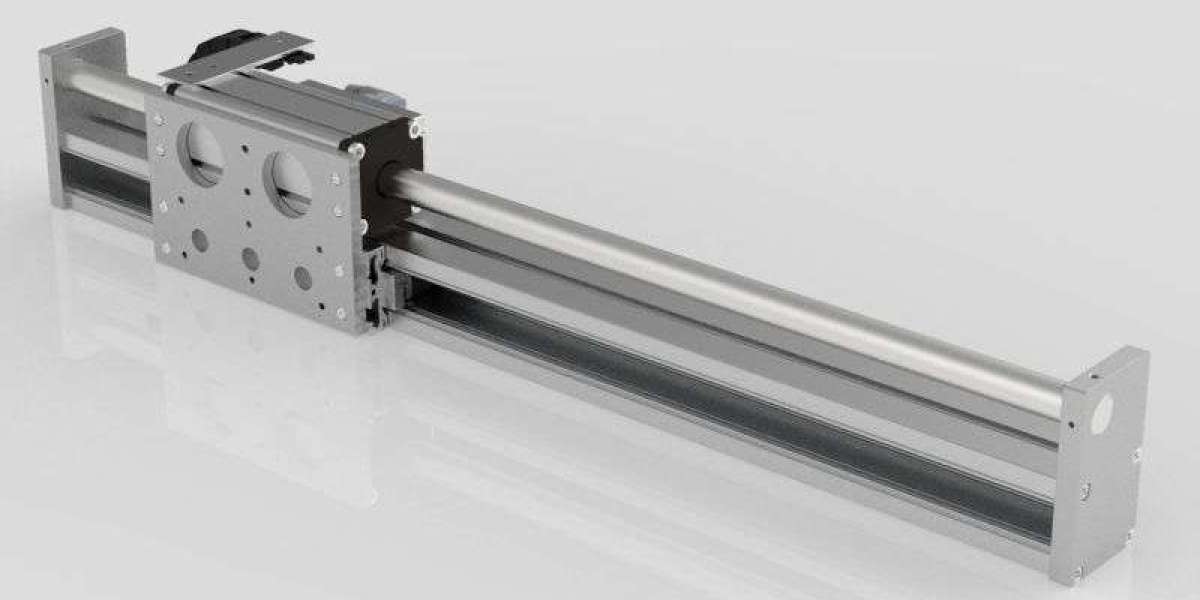

Linear Guide Bearings + Ball Screws: For multi-axis motion with high thrust (e.g., CNC mills).

Linear Guide Bearings + Belt Drives: For high-speed tasks with moderate precision.

Multi-Axis Systems: Using linear guide bearings for primary axes (X/Y/Z) and specialized bearings for auxiliary movements.

How to Choose the Right System

When deciding between linear guide bearings and alternatives, consider:

Primary Requirement: Precision, speed, load capacity, or cost?

Application Type: Heavy industry (e.g., manufacturing) vs. lightweight automation (e.g., 3D printing).

Environment: Harsh conditions may favor sealed or corrosion-resistant bearings.

Conclusion: Why Linear Guide Bearings Are a Smart Default

Linear guide bearings offer a balanced combination of precision, load capacity, versatility, and cost-effectiveness, making them the default choice for most linear motion applications. Whether you’re building a CNC machine, a robotic arm, or a 3D printer, understanding their advantages over alternative systems ensures you can select the optimal solution for your needs. For more insights or to explore premium linear guide bearing solutions, visit YH Linear Newsor browse our product catalog at YH Linear. #LinearGuideBearings #PrecisionMotion #CNC #Automation #Manufacturing #Engineering