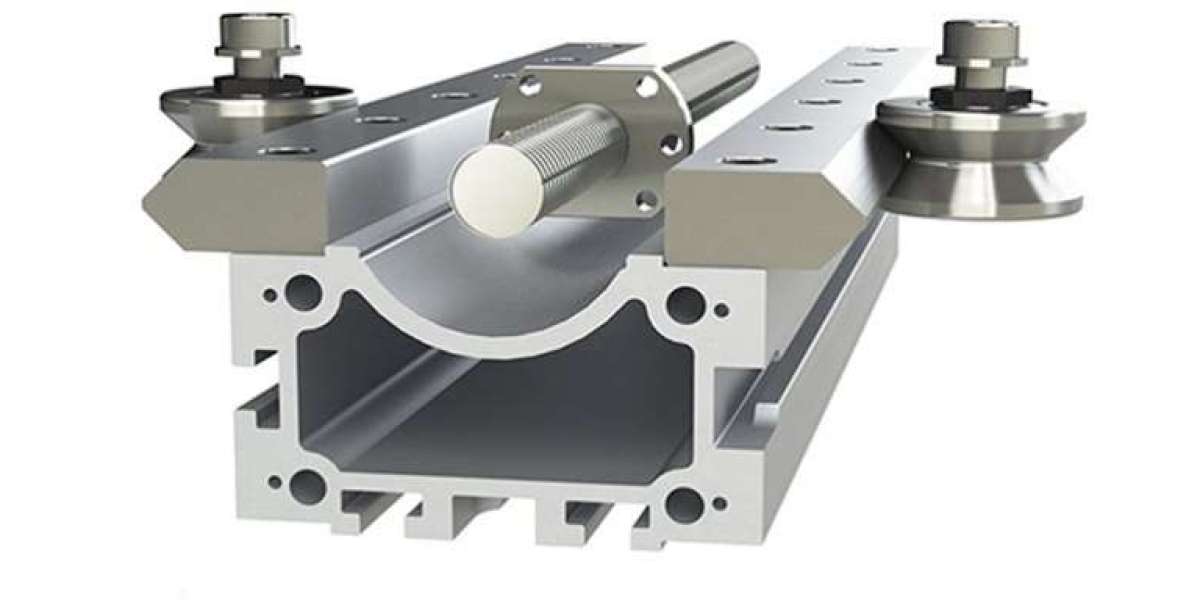

What are Linear Guide Bearings? Defining the Core Function

Linear guide bearings, often used interchangeably with terms like linear bearings or linear bushings, are specialized mechanical components designed to facilitate smooth, accurate, and low-friction linear motion. Their primary function is to allow movement along a single axis while minimizing friction and providing support for the moving element. This precise guidance is critical for applications requiring high accuracy, repeatability, and stability.

The key to a linear guide bearing's performance lies in its ability to minimize friction. This is typically achieved through the use of rolling elements, such as ball bearings or roller bearings, or through specialized low-friction materials. The design and materials used in the construction of linear guide bearings are also crucial, as they must withstand significant loads and environmental factors while maintaining their dimensional accuracy and structural integrity.

Exploring the Landscape: Diverse Types of Linear Guide Bearings

The world of linear guide bearings encompasses a diverse range of designs, each engineered with distinct features and characteristics to suit different operational requirements and application demands:

- Ball Bushing Linear Bearings: These are among the most common types, utilizing recirculating ball bearings within a cylindrical housing to provide low-friction linear motion along a hardened and ground shaft. They offer a good balance of load capacity, accuracy, and cost-effectiveness.

- Linear Ball Bearings with Cages: These bearings feature a cage that separates the ball bearings, reducing noise, increasing speed, and extending the bearing's lifespan.

- Needle Roller Linear Bearings: These bearings utilize needle rollers instead of ball bearings, resulting in higher load capacities and greater rigidity. They are often used in heavy-duty applications.

- Plain Linear Bearings (Sleeve Bearings): These bearings use a low-friction material, such as bronze or plastic, to provide a sliding surface along a shaft. They are simple, cost-effective, and can operate without lubrication in some applications.

- Profiled Rail Linear Guides (incorporating bearings): While technically a complete system, the bearing component within a profiled rail linear guide is a crucial element. These systems offer exceptional rigidity, load capacity, and accuracy, making them ideal for demanding applications.

Applications Across Industries: Where Linear Guide Bearings Excel

Linear guide bearings are essential components in a wide range of industries and applications, enabling precise and controlled linear motion:

- CNC Machines: Providing accurate and stable tool and workpiece positioning for milling, turning, and other machining operations.

- Robotics: Enabling precise and repeatable movements in robotic arms, linear actuators, and other robotic systems.

- 3D Printers: Controlling the movement of the print head and build platform for accurate layer deposition in additive manufacturing processes.

- Medical Devices: Providing smooth and precise motion in medical imaging equipment, surgical robots, and laboratory automation systems, ensuring patient safety and diagnostic accuracy.

- Automation Equipment: Enabling efficient and reliable linear movement in automated assembly lines, packaging machines, and material handling systems.

- Semiconductor Manufacturing: Providing precise positioning and movement in wafer handling equipment and other semiconductor manufacturing processes, where extreme cleanliness and accuracy are paramount.

- Aerospace: Used in aircraft control surfaces, landing gear actuators, and other aerospace applications where high performance and reliability are essential.

Selecting the Right Linear Guide Bearing: Key Considerations

Choosing the appropriate linear guide bearing for a specific application requires careful consideration of several key factors:

- Load Capacity: The bearing must be able to support the applied load without deformation or failure. Consider both static and dynamic loads, as well as any shock loads that may occur during operation.

- Accuracy and Precision: The required level of accuracy and precision for the linear motion will dictate the type of bearing needed.

- Stiffness: The stiffness of the bearing will affect the amount of deflection under load.

- Speed and Acceleration: The bearing must be able to handle the required speed and acceleration without excessive wear or vibration.

- Operating Environment: The operating environment, including temperature, humidity, and exposure to contaminants, will influence the selection of materials and lubrication.

- Travel Length: The required travel length of the linear motion will determine the length of the bearing needed (for sleeve bearings) or the overall system (for profiled rail guides).

- Mounting: The bearing must be mounted securely to a rigid structure to prevent vibration and maintain accuracy.

- Cost: The cost of the bearing is an important consideration, but it should be balanced against the performance and reliability requirements of the application.

Installation and Maintenance Best Practices

Proper installation and meticulous maintenance are absolutely essential for maximizing the long-term performance, reliability, and lifespan of linear guide bearings. Key best practices include:

- Precise Alignment: Ensure that the linear guide bearings are precisely aligned to prevent uneven wear, binding, and premature failure.

- Secure Mounting: Mount the linear guide bearings securely to a rigid and stable structure to minimize vibration, prevent deflection, and maintain overall accuracy.

- Adequate Lubrication: Adhere strictly to the manufacturer's recommendations for lubrication type and frequency. Regular lubrication is absolutely essential for minimizing friction, reducing wear, and preventing corrosion.

- Cleanliness and Contamination Control: Implement measures to keep the linear guide bearings clean and free from contaminants such as dirt, dust, and debris.

- Regular Inspection and Monitoring: Establish a schedule for regular inspection of the linear guide bearings to identify any signs of wear, damage, or misalignment. Promptly replace any worn or damaged components to prevent further damage and ensure continued reliable operation.

Conclusion

Linear guide bearings are indispensable components in modern automation and industrial systems, providing the foundation for precise and efficient linear motion across countless applications. By understanding the different types of bearings, their applications, and the key factors in their selection, installation, and maintenance, engineers and designers can optimize their systems for peak performance, exceptional accuracy, and unwavering reliability.