Procurement Resource, a globally renowned provider of market research and procurement intelligence, proudly announces the release of its latest Fluorosilicone Rubber Production Cost Report. This report serves as a vital tool for stakeholders, manufacturers, investors, and supply chain strategists looking to explore, invest, or expand in the high-performance elastomer market.

This exhaustive report offers a complete breakdown of the cost structures, production pathways, market trends, raw material sourcing, and operational considerations essential for the successful and cost-effective production of Fluorosilicone Rubber (FSR).

Fluorosilicone Rubber: A High-Performance Elastomer for Extreme Conditions

Fluorosilicone Rubber (FSR) is a class of elastomers based on fluorinated silicone polymers. Known for their excellent thermal stability, chemical resistance, and flexibility, FSRs are engineered to perform in harsh environments where traditional silicones or rubbers would degrade.

Key Applications:

- Aerospace: Seals, gaskets, and O-rings exposed to jet fuels and extreme temperatures

- Automotive: Under-the-hood components, fuel systems, turbochargers

- Industrial and Electronics: Harsh chemical environments, sensors, and sealing solutions

- Military and Defense: Specialized elastomer components for mission-critical systems

FSR offers the unique advantage of combining the heat resistance of silicone with the fuel and solvent resistance of fluorocarbon elastomers, making it indispensable in sectors where reliability under stress is paramount.

In-Depth Production Cost Report: Strategic Planning

The Fluorosilicone Rubber Production Cost Report by Procurement Resource is a comprehensive guide designed to support companies aiming to set up or optimize an FSR production facility. Covering all technical, financial, and operational aspects, this report helps businesses reduce risk and improve profitability through data-backed decision-making.

Market Overview:

Global Trends and Regional Insights

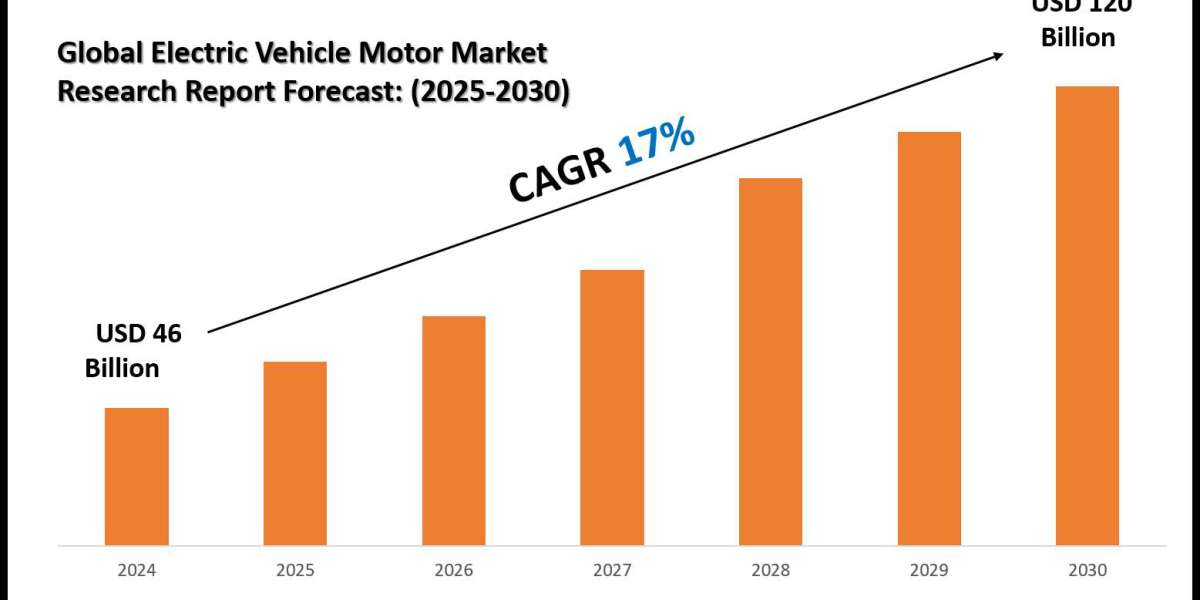

Driven by rising demand in aerospace, automotive, and specialty sealing applications, the global market for Fluorosilicone Rubber is witnessing steady growth. North America, Europe, and Asia-Pacific lead the demand, supported by robust defense and automotive sectors.

Countries such as the United States, Germany, Japan, South Korea, and China have emerged as major producers and consumers of FSR, thanks to their developed industrial infrastructure and regulatory push for advanced, durable materials.

Raw Material Supply Chain and Pricing Trends

FSR production relies on specialized raw materials, including:

- Fluorosilane or Fluorinated Siloxane Precursors

- Silicone Oils or Polymethylsiloxanes

- Catalysts (typically platinum-based)

- Fillers (like silica) and Crosslinkers

These high-purity inputs often undergo multiple processing stages, contributing significantly to overall production costs. The report includes analysis on:

- Sourcing strategies and regional suppliers

- Import-export dynamics

- Historical and forecast pricing trends

- Supply chain disruptions and their cost impact

Technical and Operational Insights:

Production Process: How Fluorosilicone Rubber Is Made

Fluorosilicone rubber is typically synthesized by copolymerizing fluoroalkyl-functional siloxane monomers with dimethylsiloxane, followed by crosslinking into an elastomeric material.

Key Steps:

- Monomer Preparation: Production of fluorinated siloxane monomers from fluorosilanes.

- Polymerization: Copolymerization with dimethylsiloxane using catalysts.

- Compounding: Addition of fillers, heat stabilizers, pigments, and vulcanizing agents.

- Crosslinking: Using heat or catalysts (platinum or peroxide) to vulcanize the rubber.

- Finishing: Calendering, extrusion, or molding into sheets, seals, or custom parts.

The report examines various process technologies, including liquid injection molding (LIM), compression molding, and extrusion, based on the desired end-use and production scale.

Machinery and Equipment Requirements

Essential machinery for an FSR plant includes:

- Polymerization reactors with inert atmosphere capability

- High-temperature mixing and blending systems

- Precision molding and extrusion equipment

- Heat-curing ovens or autoclaves

- Quality testing and inspection units

- Storage for temperature-sensitive raw materials

The report outlines specifications and cost estimates for fully-automatic, semi-automatic, and batch process setups.

Infrastructure and Utility Needs

The infrastructure layout includes:

- Controlled-environment production halls

- Specialized ventilation and fume extraction systems

- Power backup systems due to high-temperature curing needs

- Cooling water and thermal oil systems

- Safe storage of hazardous and sensitive chemicals

Utility analysis includes electricity, nitrogen/inert gas requirements, and water for cooling and cleaning operations.

Workforce and Skill Set Requirements

Due to the technical complexity of FSR production, highly skilled personnel are necessary. The report outlines the manpower required, such as:

- Polymer chemists and chemical engineers

- Process technicians for extrusion/molding

- Quality control experts

- Maintenance and EHS staff

- R&D specialists for formulation adjustments

Training in hazardous material handling and precision processing is a crucial part of plant operation.

Quality Assurance and Regulatory Compliance

FSR products, especially for aerospace and defense, must comply with strict quality and material standards, including:

- ASTM D2000, AMS, and MIL-SPEC standards

- Flame, smoke, and toxicity compliance (FST)

- Thermal aging, fuel resistance, and low-temperature flexibility tests

- ISO 9001 / AS9100 certification for plant operations

The report includes QA protocols and testing equipment required to ensure consistent product performance.

Financial and Economic Evaluation:

Capital Investment Overview

The report provides cost estimates for:

- Land and plant construction

- Equipment and installation

- Licensing and certification

- Initial raw material inventory

- Training, insurance, and pre-operational expenses

CAPEX modeling is offered for various scales (e.g., pilot, mid-scale, commercial).

Operating Cost Analysis

Breakdown of recurring expenses includes:

- Raw materials and additives

- Utilities (power, cooling, inert gases)

- Labor and staff salaries

- Maintenance and spare parts

- Packaging, logistics, and waste disposal

- Regulatory compliance and certifications

Detailed cost-per-kg analysis is provided for comparison across different production scales.

Profitability and Return Metrics

Based on current market prices and forecasted demand, the report calculates:

- Gross margin and EBITDA

- Return on Investment (ROI)

- Net Present Value (NPV)

- Internal Rate of Return (IRR)

Market segment-specific profitability (e.g., automotive vs. aerospace) is also assessed.

Break-Even and Payback Period

Understanding financial risk is essential in specialty rubber manufacturing. The report features:

- Break-even analysis

- Payback period projections

- Sensitivity analysis based on fluctuations in raw material and energy costs

Sustainability and Emerging Opportunities

As environmental regulations tighten, FSR manufacturers are exploring:

- Solvent-free and low-VOC production methods

- Recyclable or reclaimable FSR compounds

- Bio-based silicone intermediates

- Cleaner curing systems (plasma, UV, microwave)

Europe and North America are leading the way in sustainable material innovation, while Asia-Pacific offers cost-competitive manufacturing hubs. The report evaluates upcoming trends, regulatory pressures, and funding opportunities for green FSR initiatives.

Why Choose Procurement Resource?

With a proven track record in chemical, polymer, and specialty material sectors, Procurement Resource delivers strategic insights that go beyond basic reporting. Our solutions include:

- Detailed production cost modeling

- Customized feasibility and investment reports

- Supply chain and procurement optimization

- Market entry and expansion strategy consulting

We empower clients to reduce costs, mitigate risks, and achieve long-term growth through our data-driven approach.

Request a Free Sample Report

If you're exploring opportunities in Fluorosilicone Rubber manufacturing, the Procurement Resource Production Cost Report is your blueprint for success. From financial forecasting to operational planning, this report helps you make strategic decisions with clarity.

Request a Free Sample Report: https://www.procurementresource.com/production-cost-report-store/fluorosilicone-rubber/request-sample

About Procurement Resource

Procurement Resource is a global leader in providing procurement intelligence, cost modeling, and supply chain insights across sectors including chemicals, polymers, automotive, energy, and pharmaceuticals.

Services Offered:

- End-to-end production cost and investment reports

- Custom market research and demand analysis

- Procurement planning and vendor benchmarking

- Data-backed strategy formulation for growth and efficiency

Contact Information

Company Name: Procurement Resource

Contact Person: Ashish Sharma (Sales Representative)

Email: sales@procurementresource.com

Location: 30 North Gould Street, Sheridan, WY 82801, USA

Phone:

UK: +44 7537171117

USA: +1 307 363 1045

Asia-Pacific (APAC): +91 1203185500

Connect With Us Online:

https://www.linkedin.com/company/procurement-resource-official/