What is an industrial power distribution system? Key components and system architecture Different types of industrial distribution (LV, MV, and smart systems) Applications across major industries How Degatech Electric provides reliable, high-performance industrial power solutions

What Is an Industrial Power Distribution System?

High power loads Continuous or variable demand Harsh environments (dust, heat, moisture, corrosive atmospheres) Safety and reliability requirements for uninterrupted production

Low Voltage (LV): Up to 1kV – for control panels, motors, lighting Medium Voltage (MV): 1kV – 36kV – for larger machinery, motors, substations

Key Components of Industrial Power Distribution Systems

1. Medium Voltage Switchgear

Used for incoming power from utilities or generators, often in the range of 6kV – 36kV. Provides protection, isolation, and control. Often includes vacuum or SF₆ circuit breakers, though vacuum is preferred for safety and environmental reasons.

2. Transformers

Step down high voltage to usable levels (e.g., from 10kV to 400V or 690V). Can be dry-type or oil-immersed depending on the environment.

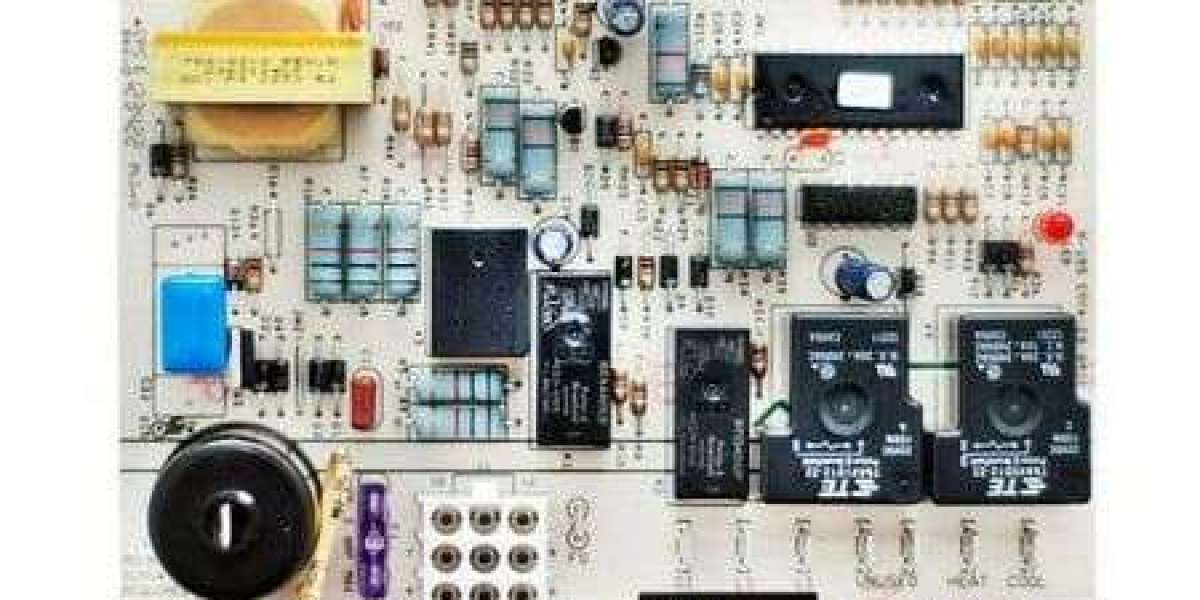

3. Low Voltage Switchboards & Panelboards

Distribute power to individual machines, motors, conveyors, and control circuits. Include circuit breakers, busbars, and protection devices.

4. Motor Control Centers (MCCs)

Used for starting, stopping, and controlling industrial motors. Often integrated with VFDs (variable frequency drives).

5. Cables, Busbars & Conduits

Transport electricity safely across the facility. Must be selected based on load, environment, and safety codes.

Types of Industrial Power Distribution Systems

Applications Across Key Industries

Manufacturing & Assembly Plants Powering conveyor belts, robotics, CNC machines, and assembly lines.

Mining & Metals Heavy-duty distribution for drills, excavators, crushers, and ore processing.

Oil & Gas / Petrochemical Explosion-proof and corrosion-resistant systems for hazardous areas.

Power Generation (Thermal, Hydro, Renewable) Distribution between turbines, generators, transformers, and switchyards.

Data Centers & Critical Infrastructure High-availability power with redundancy and UPS integration.

Cement, Pulp & Paper, Chemicals Continuous operation and high-load motor distribution.

Trends in Industrial Power Distribution (2024 and Beyond)

Digitalization & Smart Monitoring IoT-enabled circuit breakers, energy management systems, and predictive maintenance.

Energy Efficiency & Sustainability Use of energy-efficient transformers, VFDs, and smart controls to reduce waste.

Modular & Prefabricated Systems Faster installation, easier scalability, especially for new plants or expansions.

Safety & Compliance Increased focus on arc flash protection, grounding, and hazardous area certifications.

Integration with Renewables Industrial sites are increasingly using solar, battery storage, and microgrids.

Why Choose Degatech Electric for Industrial Power Solutions?

High-quality MV/LV switchgear for harsh industrial environments Vacuum circuit breakers with long life and low maintenance Customized and modular designs for unique plant layouts Global export and technical support

Reliable uptime Operator and equipment safety Energy efficiency and cost savings